Cardboard Boxes

Why do people use cardboard for packaging?

For a variety of storage and packing needs, cardboard packaging is a great, affordable option. You can use cardboard packaging for a wide range of goods and products, and as a business, you can lower your costs and carbon footprint while ensuring that products reach your customers unharmed. Cardboard boxes and cardboard drums offer a surprising high level of protection, are great value, incredibly versatile, and environmentally friendly.

What Purposes Does Cardboard Packaging Serve?

The uses for cardboard packing are many and it is highly adaptable. Protecting products (often solid items) that need to be stored and moved is the main objective of cardboard packaging.

This is a broad perspective on cardboard packing because, in reality, cardboard can be used to store anything from home products to electrical equipment. Businesses pack orders in cardboard boxes to ensure that they reach their consumers undamaged and utilize cardboard boxes to send things in bulk.

Cardboard can be used to store food and beverages (such as milk cartons), and in some situations, cardboard drums are even used to convey harmful trash, dangerous chemicals, and pharmaceuticals.

Cardboard boxes are utilized by private citizens, tiny corporations, and huge industrial organizations, to name a few.

A cardboard box can certainly be used to ship an item if it needs to be shipped!

Various Forms of Cardboard Packaging

There are many various packing solutions, which is why cardboard is so adaptable. Although it is simple to mass create cardboard, it may also be customized to fulfill unique needs, transport, and protect certain products.

However, despite the fact that cardboard comes in a variety of sizes and forms, there are three main types of cardboard packing that are frequently used for industrial shipping and storage.

As follows:

- Cardboard boxes with one wall;

- Cardboard boxes with two walls;

- Drums made of fiber;

The cheapest choice, which provides a reasonable amount of protection, is single-walled cardboard boxes because they are light and versatile. Although more expensive and heavy, double-walled cardboard boxes provide an additional layer of protection despite having two layers of cardboard.

Fibre drums are spherical containers made of fibers of hard cardboard. They provide a high level of security and can be equipped with drum liners to store both solids and liquids. Fibre drums, which are of food-grade quality and are frequently used for food storage, are also UN-rated for the transportation of dangerous or hazardous items.

Is Cardboard a Good Material for Packaging?

An great packaging material is cardboard. While high-quality cardboard is sturdy, resilient, and able to endure a surprising amount of damage, cardboard boxes may initially appear flimsy.

To better understand why cardboard packaging is a smart decision, let’s examine its main benefits in more detail.

Versatile

As we’ve already seen, cardboard packaging is incredibly adaptable and has a wide range of applications. Boxes and drums made out of cardboard can be produced in practically any size.

Additionally, cardboard can be used to brand products with company logos or to give customers instructions or cautions. As a result, cardboard packing may become crucial to a company’s branding and marketing efforts.

Cost-Effective

Packaging made of cardboard is definitely more affordable. It’s one of the most affordable types of packaging you can get for your company, especially if you’re filling orders in volume.

However, like with any packing product, you shouldn’t just choose the least expensive choice. Always choose high-quality cardboard packing, even if it costs a little extra. After all, you don’t want your clients to receive products in poor condition or in subpar packaging.

Durable

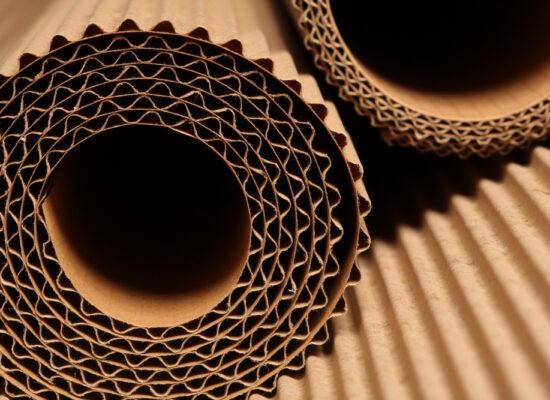

The purpose of cardboard packaging is to protect whatever is kept inside, and it excels at this task. Corrugated cardboard is used between two layers of cardboard to create cardboard boxes.

This provides a springy layer of protection to guard against damage to the items. Boxes made of cardboard are somewhat waterproof and can be scraped, dented, and knocked around.

Is cardboard a green material?

Cardboard packaging has many benefits, one of which is that it is environmentally friendly. If cardboard boxes cannot be reused more than once, they can be recycled to create new items.

Recycling makes it easier for cardboard manufacturers to keep prices low, which benefits businesses by allowing them to find less expensive cardboard for their storage and transportation needs.

By using cardboard packaging instead of other materials like plastic, businesses are able to reduce their carbon footprint and, as a result, create a more sustainable, ecologically friendly brand that their eco-aware clients will be glad to work with.

How Can Cardboard Be Made Stronger?

How to make cardboard stronger for safer storage and shipping may come up if you need to ship very precious or delicate products.

It’s usually better to start by making an investment in premium cardboard boxes from a dependable supplier. Second, always use sturdy double-walled cardboard boxes over more affordable single-walled cardboard boxes.

You could double-wall a box or add additional cardboard inserts to the wrapping. It is advised to pack everything firmly to prevent shifting during transit and, if necessary, to think about wrapping individual objects in thin cardboard or paper sheets.

Check the cardboard box for rips, tears, and structural damage before shipping. Use only strong, unbroken boxes because damage that is already there can easily made worse during delivery.

Unexpectedly resilient for its size, cardboard packaging may be utilized to properly carry and store a variety of commodities and products. Cost-efficient, adaptable, and most importantly, environmentally friendly, cardboard packing is a great choice.

Cardboard Boxes For Food

Even ecologically concerned businesses continue to use corrugated cardboard as their primary packaging material in a world where excessive use of paper-based products is frequently seen as being unmindful of the environment.

This is due to a number of factors. Corrugated cardboard offers a high level of protection at a low cost that just cannot be matched by most alternatives. It is also very versatile and customizable.

However, let’s go a bit further. Here are the primary arguments for why corrugated cardboard is still dominant:

Recyclable

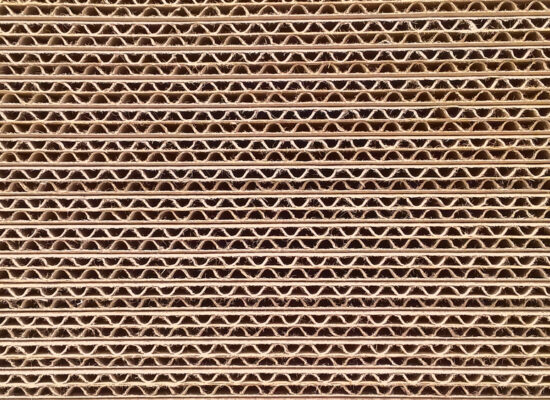

Corrugated board is a recyclable form of packaging made from materials like discarded cardboard cartons and outdated newspapers. Some corrugated board is even created from 100% recycled materials, making it one of the most extensively recycled materials in the world. The average content is between 70 and 90 percent recycled materials, which is still far superior to packaging made of plastic and wood.

Furthermore, corrugated cardboard is frequently made without the use of colors or bleaches, which further reduces its environmental impact and degree of recyclable materials.

Corrugated packaging can also be reused; frequently, cartons are folded and kept for later use in homes, workplaces, and some retailers.

Energy-Efficient

Corrugated cardboard’s reuse and recycling has a knock-on effect that lowers the energy and other resources needed to make it in the first place.

Corrugated packaging requires significantly less energy to make because it is made responsibly using a large percentage of recycled materials. Transportation expenses for manufacture remain cheaper than if the materials were to be imported or freighted great distances because they are frequently made from locally accessible recycled materials.

Overall, cardboard has developed into one of the most environmentally friendly logistical packaging options available worldwide.

Corrugated cardboard box

When it comes to packing, corrugated cardboard is a popular option across a variety of industries. It is simple to form and store. It is lightweight and keeps things secure. Every day, many people use these cardboards.

What Is a Corrugated Cardboard Box?

Corrugated cardboards are essentially paper-based packaging supplies. They are frequently beige, but depending on the needs, they might also be created in other colors. Despite having a history dating back to the 1800s, they are currently the most often used packaging material. They can be recycled because they are made of paper, making them a viable option for businesses and individuals who care about the environment.

Corrugated cardboard: How is it made?

One or more corrugated paper layers are sandwiched between two flat paper layers to create corrugated cardboards. Depending on the quantity and type of corrugated layers, they take on various styles. Many corrugated cardboard box producers produce the boxes using both new and recycled paper. These boxes are produced in large quantities using specialized equipment that can cause wetness and make corrugated parts. The production process includes a drying step as well. These cardboards require a lot of energy to make, as is evident from the production methods.

The Corrugated Cardboard’s 5 Advantages

A cardboard corrugated box is useful in a wide range of industries. Corrugated cardboards have many benefits when it comes to packing, which is why.

- Recyclable corrugated cardboard is available.

- They are simple to carry, shape, and confine.

- They are conducive to health.

- They are lightweight and reusable, as well as strong.

What are the Different Corrugated Cardboard Sizes and Types?

Sizes and varieties of corrugated cardboard boxes vary due to the variety of uses they have in industries like food, e-commerce, architecture, and interior design. Pizza boxes are an example of a corrugated food box. Corrugated cardboard can also be used for product packaging, banners, and modeling.

What are Some Tips for Picking the Correct Size and Type of Corrugated Cardboard?

The first thing you should consider when picking a corrugated cardboard is knowing the difference between a corrugated box and a cardboard box. Isn’t a factory supply cardboard box corrugated, you might wonder? No, is the response. Corrugated boxes appear to be similar, but because they are built of several layers, they are far more durable. Understanding your packaging demands should be another area of focus. Avoid selecting a corrugated cardboard that is inappropriate for your product.

How Should Corrugated Cardboard Boxes Be Stored and Cared For?

Boxes made of corrugated cardboard can be reused numerous times because they are quite resilient. Because of this, it could be a good idea to take good care of them and store them carefully. They can be heaped up in your storage area because they are lightweight and don’t have particularly tall sides. Additionally, they won’t decay as long as they are handled gently during use, storage, and transportation.

Presentation Boxes and a Stand

The stand and display boxes specifically created for the brand are one of the best ways to convey the brand and product message to the customers. By designing a specific sales space outside the shelf in your concept area, you can use product sales stands to highlight your brand. Additionally, its flexibility within the retail area and advantage of mobility make it possible for your brand to be seen in any retail setting.

E-Commerce Boxes

Although shipping has been utilized in the past and is still used today, the extensive usage of online shopping has increased the importance of product packaging. The quantity and variety of packaging components used in sales have increased as a result. You should be fully informed about e-commerce boxes, particularly if you are a business owner or frequently utilize boxes.

The Importance of E-Commerce Boxes

First and foremost, e-commerce shipping boxes are crucial for client happiness. E-commerce shipping carton boxes shield the item and make sure it gets to the consumer in the best condition possible. Determining the best e-commerce packaging boxes for the shipping goods is crucial.

How Do You Pick the Best E-Commerce Box for Your Company?

It is vital to take into account a few fundamental aspects in order to choose the best e-commerce packaging boxes. One of the first factors that needs to be considered is the size of the goods, the material of the box, the texture and appearance of the box, the expenses, and any potential for damage.

Take Your Product’s Size And Dimensions Into Account

The merchandise may be shaken during shipping if the supplied item is small in relation to the e-commerce shipping box. As a result, the item could be harmed. Similar to how smaller cartons for the bigger things could tear.

For Your E-Commerce Box, Choose the Right Material

Even though the item’s size and overall cost are significant, getting the product to the consumer without any form of damage should come first. Only by choosing the appropriate material for the e-commerce box is this feasible.

Select a Box That Represents Your Brand

Being unique is one of the most crucial elements of branding. Having a distinctive design makes it easier to stand out to customers. This comprises the product and package both having a distinctive design. You should focus on the caliber and originality of the packaging if you want to run a profitable and memorable firm.

Take into account the Shipping and Handling Requirements.

The shipping regulations for e-commerce boxes in the USA and the UK, for instance, could differ. It is crucial to consider the shipping and handling requirements as a result. However, handling specifications may vary depending on the supplied item as well.

For Your Business, the Top 8 E-Commerce Boxes

There are many e-commerce boxes that are frequently used by numerous businesses. You may pick which kind of boxes are best for your items and business based on the aforementioned considerations.

The Regular Brown Box

One of the most popular kinds of e-commerce boxes is the plain brown box. Soft objects that won’t be harmed by the environment are most suited for it.

The Cardboard Box

The cardboard used in e-commerce corrugated boxes is made up of three layers of paper, and consumers favor them for their durability, environmentally friendly design, and affordable price. The corrugated cardboard boxes are great for transporting and long-term storing a variety of products.

Box for shipping

Larger products are typically placed in the shipping boxes. By using tape and folding the box, you may give it a dimension.

Storage Boxes are also referred to as containers. They are typically hard, and some of them have covers.

Die-Cut Box

Die-Cut boxes have covers that are built with a particular opening and closing mechanism. So there is no need for any kind of taping or gluing.

The Folding Carton

Folding cartons are specifically shaped to have a cover that can be closed practically and a cylinder shape.

The Custom Box

Custom boxes can be created to reflect your brand, personal preferences, and the characteristics of your product. Even when the product is removed from the box, custom boxes help the brand stand out.

Boxes for Industry

Both the transportation and shelf display processes benefit from the use of corrugated cardboard in food and beverage packaging. One of the top priorities is to provide safe transportation, sustainability, and hygienic production conditions.

Boxes of food

A crucial advertising space is created by shelf-ready presentation packaging, which firms may use to engage with consumers and influence their purchasing decisions. Packaging has a direct impact on consumer decision-making. Shelf-ready presentation packages should be eye-catching, protected, and not destroyed throughout the time it takes to get on the shelf in a sector with intense rivalry like the retail business.

Chicken and Meat Crates

Storage conditions must be taken into consideration in the post-production logistics process for food goods like beef and chicken that must be delivered in the cold chain.

Boxes Of Pizza

What Kinds of Pizza Boxes Are There?

There are numerous different pizza box designs available nowadays for various pizza shops. These pizza boxes vary primarily depending on the restaurant’s preference for the kind of pizza they provide. Pizza boxes come in a variety of shapes and sizes, including miniature pizza boxes, ziplock bags, and corrugated cardboard ones.

Where Can Pizza Boxes Made of Cardboard and Corrugated Be Used?

Pizza is frequently packaged in cardboard pizza boxes or corrugated pizza boxes. Undoubtedly, there are particular reasons behind that. Pizza boxes made of cardboard or corrugated are lightweight in the first place. This element is crucial to take into account because carrying and storing the boxes would likely become very difficult otherwise. The price is still another factor. One of the least expensive packaging materials is cardboard and corrugated cartons. This is so they can be made quickly. They are typically utilized in pizza franchises and eateries. After finishing their pizza, people can even use them in their houses. They can use them to keep leftovers or serve meals in them. Pizza boxes made of cardboard or corrugated material can be reused multiple times because they are rather resilient.

What Sizes Do Pizza Boxes Come In?

The boxes used vary due to the wide variety of pizza establishments and pizza varieties. Pizza boxes typically have sizes that are similar to one another. Typically, restaurants provide small, medium, and large box pizzas.

What Do Pizza Box Designs Entail?

When it comes to their design, pizza boxes need specific consideration. They ought to be able to carry the brands and styles of the firms while also withstanding the wetness and grease that hot pizza exudes. After all, your company will be represented by these boxes. Having high standards for representation is only right.

How come pizza boxes are square?

Why square boxes are used for round pizzas is a common mystery. To start, square boxes are more useful than other shapes. They are simpler to create and only need one piece of cardboard. Square boxes can be conveniently stored and stacked at the same time. Last but not least, there are voids left when a round pizza is placed in a square box, making it simpler for individuals to take pieces. Pizza-serving establishments may fill these areas with various sauces or toppings.

How Are a Locked Pizza Box’s Design and Production Processes Conducted?

For a variety of reasons, many individuals prefer to eat their pizza in a lockable pizza box. After the pizza is placed inside, a lockable pizza box is entirely shut. The box can only be opened by tearing a piece of it or destroying it. Since no one can touch the customer’s food while it is being transported, they feel safer.

Can You Recycle Pizza Boxes?

Pizza boxes are typically made of corrugated cardboard, which is a recyclable material. Actually, this is still another reason why pizzas are packaged in corrugated cardboard.

Where can I find pizza boxes in bulk?

Buying pizza boxes in bulk is a really wise decision. In general, purchasing something in bulk is more profitable. Since these boxes are quickly used, they must constantly be on hand for packaging. You can purchase in bulk to guarantee that you never run out of boxes.

How Can I Find the Cost of a Pizza Box?

Prices for pizza boxes vary depending on a variety of factors. The cost of your purchase may vary according on the sizes, designs, styles, and numbers you choose. Without knowing the needs of the customers, a precise pricing cannot be determined. To find the greatest price that fits your demands, get in touch with us. For us, it will be a pleasure.

Fresh Fruit and Veggie Boxes

You’ll need a strategy to protect your products from harm, moisture, and other problems if you acquire and sell products. The most popular and wholesome way to package your goods is in cardboard boxes designed for produce like vegetables and fruits.

Why Use Cardboard Fruit and Vegetable Boxes?

Cardboard produce boxes are preferred for packing for a number of reasons, besides the fact that it is the traditional approach.

Cost-Effective

Given that they are made of cheap materials, cardboard product boxes are affordable goods. As a consequence, you can get a large number of produce boxes in bulk for a fair price.

Customizable

Totally customized fruit and vegetable trays are available. Your fruit and vegetable boxes can be ordered in any color and form.

Eco-Friendly

The most environmentally friendly packing for produce is cardboard. Cardboard is easily recyclable and biodegradable because it is made from renewable organic wood.

Solid and long-lasting

Produce cartons are composed of unfinished wood, making them strong and long-lasting.

Versatile

Carton made of cardboard has several uses. They can easily be utilized for a range of tasks.

How Should I Use Cardboard Fruit and Vegetable Boxes?

Produce trays made of cardboard are frequently used in many different contexts. They are one of the most adaptable packaging materials, as we already discussed, and have a variety of uses.

For Produce Arrangements

Produce displays in supermarkets commonly make use of packaging boxes. The main justification is that cardboard is a healthy and natural substitute for other materials, like plastic. Furthermore, it is straightforward to reuse the product’s original packaging because the majority of fruits and vegetables are delivered to markets in fresh fruit cardboard boxes.

Concerning Shipping and Transportation

Frequently, corrugated produce boxes are used for shipping and moving organic goods. The main benefit of using cardboard selecting bins in transportation, other the fact that they are made of healthy materials, is that because of their softer surface, cargo is less likely to be squished and damaged while in transit. The best option for transporting and moving fruit is hence to use fruit shipping boxes.

For Storage

A common and healthful method of food storage is in fruit and vegetable cartons. For the packaging of fruit and vegetables, supermarkets and retailers often choose to create their own boxes.

Guidelines for Using Cardboard Fruit and Vegetable Boxes

The produce carton is available in a variety of styles, dimensions, and hues, so you must be attentive to choose the best one. We have some advice for you if you want to get the greatest vegetable and fruit package!

Select the Correct Size

Size is important while choosing fruit packaging boxes. The type of goods you plan to package will determine the ideal size of boxes for fruit. For instance, cardboard apple boxes are the greatest option if you’re going to package apples, whereas peach boxes are the finest option if you’re going to package peaches.

Consider the Amount

When making a purchase decision for carton boxes, both quality and quantity are crucial considerations. You will likely want a lot of carton boxes if you own a business or sell produce. Typically, buying cardboard produce cartons in bulk is more affordable. Additionally, having extra cartons is usually good because you never know when you’ll need some extra cardboard fruit boxes.

Safeguard Against Moisture

Make sure the fruit or vegetable packaging box is moisture-resistant when choosing one. Use the correct wax-lined cartons to keep your fruits and veggies dry and free from moisture.

Properly ventilate

Food and other organic items need ventilation to maintain their quality. As a result, you ought to utilize cardboard fruit containers with adequate ventilation for packaging fruits and vegetables.

Clearly Label

Selecting customisable fruit storage boxes and vegetable packaging is always a good idea as labeling is crucial when selling goods. Your ability to distinguish between your products and market them to customers more successfully will depend on the cardboard box you use.

Separators for Viols

Separators and viols are required when more than one product is packaged together or when the conveyed commodity is delicate. An apple, a bottle, a piece of machinery, or a car could all be the object being transported.

- Fruit and Vegetable Viol

After being cultivated and harvested, the products in the fruit and vegetable industry are packed into different boxes and delivered to be sold in various locations. During transit, some fruits and vegetables may come into contact with one another and result in rot and crushing. Round-shaped products may be shipped without bumping into each other or becoming damaged thanks to the specially designed corrugated cardboard vegetable and fruit tray, which makes shipping healthier than using plastic substitutes. The device, which has rounded spaces on a plate, is incredibly simple to install. The chosen fruit and vegetables are prepared by fitting them into the spherical holes on the side walls that have been folded and placed within the tray. According to the box’s size and the size of the fruits and vegetables that will be placed inside, boxes can be arranged.

- Separators for precise products

The products’ impact, vibration, etc. during shipping. Separators made to fit the product are created to shield it from physical harm. Separators are simple to install, make, and may be reused. They shield the product from hits from the top and sides. Additionally, designs that can be displayed on a shelf are created.

- Product separators for glass

Glass items are frequently packaged and transported with breakage issues. Glass products are packaged separately and a fix is sought to prevent breakage. A separator is used to keep different types of glass from touching one another during packaging and transit. This reduces the risk of cracking and breakage. The product’s design also made it possible to ship it in a variety of ways. The product may be simply taken out of the box, carried, and placed on the shelf with its separator thanks to the separators. Viewing the inside of the product from the side and the design’s aesthetic posture are further elements of the product.

Corrugated boxes meet food safety requirements

Although food safety is a concern for everyone, you may not be aware that the packaging used to carry food has a huge impact on how safe our food products are. Research demonstrates that corrugated materials, among the many choices for delivering fresh food, have significant advantages in terms of food safety and spoilage.

Risks Associated with Foodborne Pathogens

Our present food manufacturing business is amazingly hygienic and secure for both customers and factory workers when compared to the atmosphere a century ago. But that doesn’t mean that occasionally there are issues with contaminated food making it to shop shelves. When problems do arise, they have substantial and enduring impacts on both consumers and firms in the food industry. Foodborne viruses can swiftly multiply when they are present during the initial packaging and transportation process, especially in the frequently warm and humid surroundings of shipping facilities and warehouses. Consumers who consume contaminated food that has been tainted with bacteria like salmonella or staphylococcus risk developing serious illnesses or perhaps passing away. A bacterial outbreak means lost consumer trust, irrevocable brand harm, and potentially high-cost recalls or legal action for the businesses that sold the tainted food.

Food Safety Leads the Way with Corrugated Materials

Making sure that their products are safe before they reach the shelves and the hands of consumers is the best approach for businesses to stop the spread of foodborne diseases. This entails using packaging materials that prevent the development of germs and other infections, so providing the food with the safest environment possible throughout shipping.

Corrugated cardboard boxes are very successful in keeping foodborne viruses out of the food chain, according to a groundbreaking study. The corrugation process itself is what makes corrugated materials so effective; in order to glue the paper to the corrugated cardboard, materials must be exposed to temperatures above 180 degrees Fahrenheit. Shippers may be confident that their materials are clean when the food is placed in them for travel because the majority of germs cannot withstand these temperatures. Any bacteria that do survive end up imprisoned inside the corrugated fibers, where they are unable to thrive and reproduce by finding food and water.

Minimizing Food Loss And Spoilage

The type of packaging used to carry food also has a significant impact on how fresh the food is. When it comes to providing the finest shipping experience for both food producers and customers, corrugated materials triumph once more. When compared to other packing materials, corrugated boxes can keep fruits and vegetables fresher for up to three days longer, according to scientists. Producers of food simply cannot afford the hazards associated with improper packaging, excessive spoiling, or shipment of their products.

© Arbemu. All rights reserved