Steel

STEEL

While steel has various purposes in the modern world, construction is where it is most frequently used. One of the most important building materials, it is preferred for a number of reasons, but chief among them are its adaptability, comparatively low production costs, high strength, sustainability, and availability.

The shapes that structural steel is categorized into each have its own compositional characteristics that are governed by standards that vary from country to country. Get a quote from us or speak with the professionals at Arbemu if you need a steel supplier or just some experienced assistance.

A fantastic resource for building and construction is structural steel. It is used so frequently all around the world because it is dependable and adaptable for a variety of reasons.

Benefits of Steel for Structures

Strength

Steel is one of the most structurally strong building materials since it can be bent and moulded into a variety of shapes. Steel’s mechanical characteristics are influenced by a variety of factors, including its chemical composition, manufacturing method, and heat treatment.

Iron makes up a sizable portion of construction steel, but other alloys, such manganese and niobium, can significantly boost the steel’s strength. Although adding these components may ultimately make steel stronger, doing so may have a negative impact on other qualities like ductility and weldability.

Steel’s overall strength is also affected by mechanical processing; in general, the more steel is “rolled,” the stronger it gets. Steel is structurally lighter because of its extraordinarily high strength to weight ratio, which has a significant impact on building costs overall.

Cost

The most economical alternative for building, most of the time, is structural steel. With improvements to steel production techniques, productivity rates have rapidly increased over the last 30 years. A single ton of steel can be produced in a lot less time, which makes it a considerably more affordable basic material.

Construction with a Wide Range of Aesthetics

Architects and designers may now express themselves more freely and creatively without compromising any functional requirements because to steel’s adaptability.

Modern uses for steel have seen metal become more prominent in a building’s aesthetic design as well as its structural design. Steel can be easily fashioned, bent, and molded in a variety of ways, unlike wood and concrete. The usage of structural steel will be extremely advantageous for non-linear designs.

Because of its contemporary appearance, aesthetic compatibility with concrete and glass, and general transparency, many architects have begun to expose steel more and more.

Sustainability

Despite appearances, structural steel is one of the building and construction industry’s most environmentally friendly materials. Around 90% of structural steel is formed of recycled materials, making steel one of the most recycled materials.

Steel is completely recyclable and requires very little processing to do so with little impact on its viability for reusing. Steel’s carbon footprint has also been drastically decreased in the last ten years, by roughly 50%. Over the past 30 years, there has been a dramatic decline in the amount of energy used in the manufacture of steel. Steel is made with very little water as well.

Resistance to Fire

Overall, steel is a substance that cannot burn. However, when heated sufficiently, steel naturally loses integrity. The term “critical temperature” refers to the temperature at which a structural steel segment can no longer maintain its load.

The ability of steel to withstand a “fire test,” a rigorous procedure carried out in a certified furnace and meticulously examined in accordance with particular criteria that vary from nation to country, is typically used to determine steel’s resistance to fire.

Resistance to the Elements

In addition to resistance to fire, structural steel has excellent weather resistance. Utilizing steel reduces the possibility of mold or mildew impairing the structural integrity of a building. These infections flourish in porous, wet materials like wood. These issues have no effect at all on steel.

Water might compromise the structural steel’s integrity in terms of corrosion. However, there are preventative steps that may be done to stop the corrosion-induced degradation of steel, including the application of specialized protective paints and sprays (this is frequently referred to as surface treatment). Steel is frequently covered in materials that are both corrosion- and fire-resistant coatings. Termites and other pests, as well as other problems like wood rot, have no effect on steel.

Typical Formational Steel Types

Parallel Flange Channels

These U-shaped channeled beams have right-angled corners and resemble a stick of staples. Although they come in a wide range of sizes, the two sides are always the same length and parallel to one another. They are used similarly to angled sections and provide a strength-to-weight ratio that is noticeably higher.

Tapered Flange Beams

I-shaped sections known as taper flange beams come in a huge range of diameters. These are frequently used in construction for girder cross-sections. Although they have torsion (twisting) resistance, despite having a comparatively high resistance ratio, they are typically not advised when pressure is present along their length.

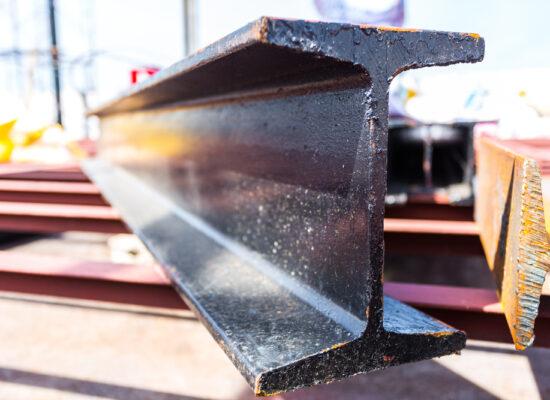

Universal Beam

I-beams or H-beams, which are other names for universal beams, have the same shape as its namesake when standing upright: a ‘I’. Among other sectors, universal beams are used in building and civil engineering and are often composed of structural steel.

Universal Column

The usage of universal beams for structural purposes is also very common. They resemble beams and are frequently referred to as I-beams or H-beams, although all three parts are the same length. They are mostly utilized for columns, as their name would imply, and they have excellent load-bearing capacities.

Sections with Angles

Equal or unequal angled structural steel sections are also possible. Both have a straight angle, but the L-shaped shapes result from the uneven parts’ different sized axes. This type of segment has substantially better strength to weight ratios and is stronger (up to 20% stronger). In residential construction, infrastructure, mining, and transportation, angled sections are used. They come in a variety of sizes and lengths as well.

Hollow circular sections

In comparison to tapered flange beams, circular hollow sections have a substantially higher resistance to torsion. They also have hollow tubular cross sections. Because the wall thickness is constant across the circle, this beam is excellent for use in applications involving several axes of loading.

Hollow rectangular sections

These have rectangular cross-sections but are similar to circular hollow sections. They are widely used in numerous steel mechanical and construction applications. They are ideal for use in joining and metal manufacturing thanks to their flat surfaces.

Hollow square sections

These are employed in smaller applications, such as columns or posts, and are similar to their hollow section brethren but have square cross-sections. However, because of how difficult it is to screw their shapes into other shapes, they are not appropriate for beams. They’re also referred to as “box parts.”

Square Sections

Steel flat portions are the most adaptable since they need to be connected to another segment. They can occasionally be used as a reinforcing tool by being fastened to another part. They are frequently referred to as “plates” as well (for example, checker plate).

What Purposes Does Structural Steel Serve?

- Steel staircases

• Steel decking

• Steel awnings & shelters

• Steel mezzanines

• Steel balustrades

• Steel gazebos

• Custom steel frames

• Steel ladder fabrication

• Steel handrails

• Steel walkways and platforms

The advantages of steel use for the environment

Steel construction has various advantages. Building with steel has advantages for the environment in addition to being a crucial aesthetic component in contemporary architecture and design, as well as being robust and versatile.

Recyclability

The ability to recycle steel is one of its amazing qualities. Repurposing or remanufacturing steel results in less destruction of our natural environment, including our trees, which are essential for removing pollutants from the air so that we may breathe it. Steel’s metallurgical characteristics ensure that there is absolutely no degradation during recycling. This indicates that it can be melted down and recycled indefinitely without suffering any damage.

Limited natural iron ore reserves need expensive mining operations that devastate numerous natural environments. Components made of recycled steel require less energy to refine, cleanse, and shape. What’s even better is that recycling the steel doesn’t weaken its strength. Recycling also prevents a significant amount of metal from entering our landfills.

Durability

For structural systems and protective coverings such exterior cladding, skins, roofs, and marine exteriors, stainless steel is a more sustainable material than wood because of its extended lifespan. For projects requiring resilience to natural factors like strong winds, dampness, and sea salt, steel construction techniques are ideally suited. Because it has anti-corrosive qualities and will not rust or break down from exposure to contaminants, stainless is particularly durable. Stainless steel is also more fire-resistant than other metal building materials, it should be highlighted. Steel is a more resilient and sustainable material, so you won’t need to mend and maintain an old structure as frequently.

Energy Savings

Steel’s energy efficiency is another advantage for the environment. Large expanses of insulation between structural parts are perfectly held in place by steel external wall systems. Rain screen facades go incredibly well with steel frame. Stainless steel panels may also be used to create these facades. Building interiors are warmer in cold weather, cooler in hot weather, and moisture-free in wet regions because to improved insulation and the system’s rapid capacity to drain moisture from the façade. This lowers the cost of heating and cooling, which reduces utility use, lessens the demand on our oil, gas, and coal sources, and also lowers the amount of electricity used.

Reusing slag and water

One of the most crucial ingredients in the manufacture of steel is water. It is mostly used for cleaning, descaling, and the chilling process. While some of this water does become contaminated during the manufacture of steel, the majority of the contaminants can be eliminated using unique filtration techniques, rendering 98% of the water reusable.

Slag, a rocky waste product removed from the metals during the smelting of ore, is another byproduct in the creation of steel. Slag used to be considered unsuitable by steel makers, and this caused some terrible environmental effects. Slag is now, however, nearly totally recycled for use in cement.

The main categories of custom steel frames

Steel is widely used in construction and building because of its extremely high tensile strength and adaptability as a material for both commercial and residential buildings.

Building walls, roof trusses, structural steel, floor systems, and roof or ceiling battens out of custom steel creates strong foundations for structures to be built on.

Building walls, roof trusses, structural steel, floor systems, and roof or ceiling battens sometimes use custom steel frames. Here are some of the main types.

Custom Steel Walls

Walls must be durable, dependable, and robust. Since of its remarkable strength to weight ratio, steel is the material of choice in modern architecture because it allows for wider spans and the creation of larger, more open areas.

Additionally, it is a very adaptable material. For commercial applications, such as offices and contemporary apartment buildings, fabricators frequently collaborate closely with architects and designers to create custom inside walls.

Custom Steel Roofs

Steel is the most durable building material available and can be incorporated into practically any roof design. Custom steel roofing has several major advantages, including:

It has the following benefits:

- It has complete design flexibility;

- It won’t increase a building’s fire load;

- It won’t rot or become infested with termites;

- It is sturdy and reasonably lightweight;

- It will always be straight and strong.

Custom Steel Floors

The best material for a building or home’s structural foundations is steel. In addition to residential construction, more complicated projects frequently include custom flooring systems. It is preferred for a number of reasons:

- Steel can be installed quickly and easily, which saves both time and money.

- It is additionally resistant to dampness and termites, which is crucial for a house’s foundations.

- Steel systems will ensure little give and are far more stiff than timber or other materials, which will reduce squeaks and bounce underfoot.

- Custom steel flooring is incredibly adaptable and will work well for construction on even the trickiest construction sites.

- Steel that has received a zinc coating is known as galvanized steel. It has a high level of corrosion resistance.

Custom Steel Stairs

Steel is frequently used in stair construction, especially for ornate and detailed ornamentation. Along with glass, steel complements popular contemporary interior design features well.

Since custom steel frames are frequently delivered ready-made and ready for erection, stairs can typically be fitted swiftly and effectively. Additionally, 3D technology makes it possible for designers and fabricators to work closely together, considerably boosting productivity and hastening the construction process even more.

© Arbemu. All rights reserved